Extraction of metal from the ore cassiterite involves

Show Hint

Crude tin obtained initially contains impurities like iron, copper, lead, and other metals.

- carbon reduction of an oxide ore

- self-reduction of a sulphide ore

- removal of copper impurity

- removal of iron impurity

The Correct Option is D

Approach Solution - 1

The important ore of tin is cassiterite \((SnO_2)\). Tin is extracted from cassiterite ore by carbon reduction method in a blast furnace. Limestone is added to produce a slug with impurities, which can be separated.

\(SnO_2+2C\rightarrow Sn+2CO\)

The product often contains traces of iron which is removed by blowing air through the melt to oxidise to FeO which then floats to the surface.

\(2Fe+O_2\rightarrow 2FeO\)

- Crude tin obtained initially contains impurities like iron, copper, lead, and other metals.

- The crude tin is subjected to a process called liquation, where it is remelted on an inclined furnace.

- Liquation takes advantage of the different melting points of tin and impurities.

- The easily fusible tin melts away and flows down, while the less fusible impurities remain behind.

- The molten tin is then further purified through a process called poling.

- Poling involves stirring the molten tin with green poles of wood in the presence of air.

- During poling, any remaining metal impurities react with oxygen in the air and form scum.

- The scum rises to the surface of the molten tin and is removed, leaving behind purified tin.

- Poling helps in oxidizing and removing the remaining impurities in the molten tin.

Therefore, Options A, C, and D are the correct answers.

Discover More From Chapter: General Principles and Processes of Isolation of Elements

Approach Solution -2

The Correct Answer is (D)

Real Life Applications

1. Cassiterite is the primary source of tin, which is widely used in the manufacturing of solder, tinplate, and other metal alloys.

2. Extracted tin from cassiterite is crucial in the production of electronic components, such as integrated circuits and transistors.

3. Tinplate made from tin extracted from cassiterite is used in food packaging, ensuring a protective and hygienic barrier for canned goods.

4. Cassiterite-derived tin is employed in coating and plating processes for items like steel containers, providing corrosion resistance and aesthetic appeal.

5. Tin is utilized in the production of solar cells, contributing to the renewable energy sector.

The extraction of metal from cassiterite ore plays a vital role in diverse industries, ranging from electronics to sustainable energy applications.

Question can also be asked as

1. What is involved in extracting metal from the ore cassiterite?

2. How is iron impurity removed during the extraction of metal from cassiterite ore?

3. Explain the process of removing iron impurity during the extraction of metal from cassiterite.

4. In the extraction of metal from cassiterite ore, what step is taken to eliminate iron impurity?

5. Describe the procedure of iron impurity removal in the extraction process of metal from cassiterite ore.

Approach Solution -3

The Correct Answer is (D)

Cassiterite ore, a primary source of tin, undergoes a series of extraction steps to obtain the desired metal. Cassiterite, also known as tin stone, is a mineral form of tin oxide (SnO2) found in various tin-bearing deposits. Tin is extracted from cassiterite ore through a sequence of extraction processes.

Removal of Iron Impurities

- Iron impurities are commonly present in cassiterite ore and need to be removed before further processing.

- Techniques such as magnetic separation or flotation are employed to separate iron-bearing minerals from cassiterite.

Carbon Reduction of an Oxide Ore

- Cassiterite is primarily an oxide ore, and tin extraction involves a carbon reduction process.

- The ore is heated with carbon in a furnace in the presence of a reducing agent, such as coke or charcoal.

- The carbon reacts with the oxygen in the cassiterite, reducing the tin oxide to metallic tin.

Smelting and Refining

- After carbon reduction, the resulting product, called crude tin or tin matte, contains impurities like copper, lead, and other metals.

- The crude tin is then subjected to smelting, where it is melted at high temperatures to separate impurities.

- During smelting, the impurities form a slag layer that floats on top of the molten tin, allowing for their removal.

Removal of Copper Impurity

- Copper impurities are commonly present in the crude tin obtained after smelting.

- To remove copper, the molten tin is stirred with green poles of wood, such as birch or fir.

- The wood reacts with copper, forming a copper oxide that floats to the surface as scum, which is skimmed off.

Purification and Casting

- Once the impurities are removed, the purified molten tin is cast into moulds or ingots for further processing and utilization.

- The cast tin can be further refined through electrolysis or other purification methods to achieve higher purity levels.

Check Out:

Top Questions on General Principles and Processes of Isolation of Elements

- On reaction of Lead Sulphide with dilute nitric acid which of the following is not formed ?

- JEE Main - 2024

- Chemistry

- General Principles and Processes of Isolation of Elements

- Given below are two statements:

Statement I : During Electrolytic refining, the pure metal is made to act as anode and its impure metallic form is used as cathode

Statement II : During the Hall-Heroult electrolysis process, purified $Al _2 O _3$ is mixed with $Na _3 AlF _6$ to lower the melting point of the mixture

In the light of the above statements, choose the most appropriate answer from the options given below:- JEE Main - 2023

- Chemistry

- General Principles and Processes of Isolation of Elements

The reaction that does NOT take place in a blast furnace between 900 K to 1500 K temperature range during extraction of iron is?

- NEET (UG) - 2023

- Chemistry

- General Principles and Processes of Isolation of Elements

Consider the following statements about the oxides of halogens

A. At room temperature, OF2; is thermally stable

B. Order of stability of oxides of halogens is I > Br > Cl

C. I2O5 is used in the estimation of CO

D. ClO2; is used as a bleaching agent

The correct statements are- TS EAMCET - 2023

- Chemistry

- General Principles and Processes of Isolation of Elements

- Which of the following ore is not in oxide form?

- GUJCET - 2023

- Chemistry

- General Principles and Processes of Isolation of Elements

Questions Asked in JEE Advanced exam

- A closed vessel contains 10 g of an ideal gas X at 300 K, which exerts 2 atm pressure. At the same temperature, 80 g of another ideal gas Y is added to it and the pressure becomes 6 atm. The ratio of root mean square velocities of X and Y at 300 K is

- JEE Advanced - 2024

- States of matter

- Let the function \(f:[1,\infin)→\R\) be defined by

\(f(t) = \begin{cases} (-1)^{n+1}2, & \text{if } t=2n-1,n\in\N, \\ \frac{(2n+1-t)}{2}f(2n-1)+\frac{(t-(2n-1))}{2}f(2n+1) & \text{if } 2n-1<t<2n+1,n\in\N. \end{cases}\)

Define \(g(x)=\int\limits_{1}^{x}f(t)dt,x\in(1,\infin).\) Let α denote the number of solutions of the equation g(x) = 0 in the interval (1, 8] and \(β=\lim\limits_{x→1+}\frac{g(x)}{x-1}\). Then the value of α + β is equal to _____.- JEE Advanced - 2024

- Integral Calculus

- A dimensionless quantity is constructed in terms of electronic charge \(e\), permittivity of free space \(\epsilon_0\) , Planck’s constant ℎ, and speed of light c. If the dimensionless quantity is written as \(e^\alpha\epsilon_0^\beta h^\gamma c^\delta\)and n is a non-zero integer, then\((\alpha, \beta,\gamma,\delta)\) is given by

- JEE Advanced - 2024

- Semiconductor electronics: materials, devices and simple circuits

- A block of mass \(5 kg\) moves along the \(x-\)direction subject to the force \(F = (−20x + 10) N,\) with the value of \(x \) in metre. At time \(t = 0 s,\) it is at rest at position \(x = 1 m\). The position and momentum of the block at \(t = (\pi/4)\) s are

- JEE Advanced - 2024

- Work-energy theorem

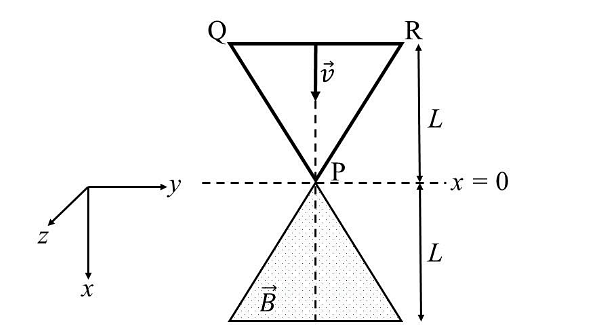

- A region in the form of an equilateral triangle (in x-y plane) of height L has a uniform magnetic field 𝐵⃗ pointing in the +z-direction. A conducting loop PQR, in the form of an equilateral triangle of the same height 𝐿, is placed in the x-y plane with its vertex P at x = 0 in the orientation shown in the figure. At 𝑡 = 0, the loop starts entering the region of the magnetic field with a uniform velocity 𝑣 along the +x-direction. The plane of the loop and its orientation remain unchanged throughout its motion.

Which of the following graph best depicts the variation of the induced emf (E) in the loop as a function of the distance (𝑥) starting from 𝑥 = 0?

Concepts Used:

General Principles and Processes of Isolation of Elements

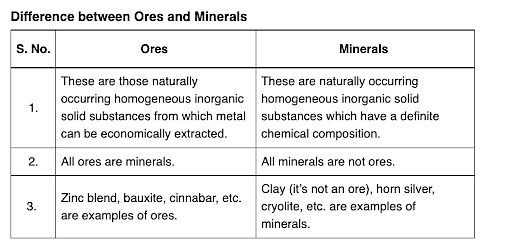

What are Ores and Minerals?

Minerals are the naturally occurring, homogeneous inorganic solid substances. They are having a definite chemical composition and crystalline structure, hardness and color. For example, copper pyrite, calamine, etc.

Impurities in an ore are called gauge. The removal of a gauge from the ore is called concentration ore.

Several steps are involved in the extraction of pure metal from ores. Major steps are as follows –

- Concentration of the ore

- Isolation of the metal from its concentrated ore

- Purification of the metal